RAILWAY TRANSPORT

Railway transport

Target Enterprises

Railway equipment repair plants

Underground

Target application

Railway car bodies

Passenger cars interior

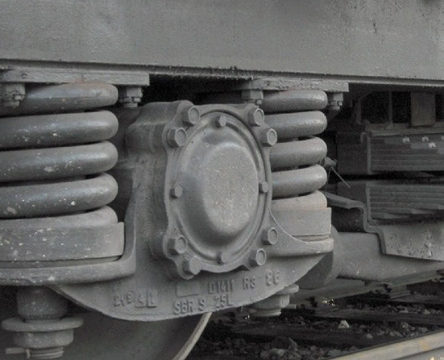

Suspension and wheel pairs

External and internal cleaning of railway tanks

Description of application

Dry ice cleaning can be used for safely removing various contaminants (epoxy resin, sealing tapes and sealants, carbon, soot, etc.) before repainting, as part of repairs and maintenance service of equipment to prevent problems.

Traction couplings, chassis systems, engine compartment, power units, interior of passenger cars and other components can be quickly cleaned without partial or complete dismantling. Dry ice cleaning significantly reduces the complexity and risks associated with the use of hazardous combustible and abrasive materials.

As a result of jet cleaning with dry ice, underground repair organizations and locomotive repair plants can significantly reduce cleaning costs.

Using cryogenic blasting, you can perform:

— in the field of» Repair of railway trains » it is possible to implement fast cleaning of wheel pairs and all components under the car and above the car directly in the shop, without chemicals and water, with the effect of degreasing;

— in the field Of «preparation of tanks for filling» you can use fast cleaning of tanks from the outside of oil residues directly in the shop, without chemicals and water, with the effect of degreasing;

— in the field of «Sale and repair of wheel pairs» it is possible to implement fast cleaning of wheel pairs directly in the shop, without chemicals and water, with the effect of degreasing;

— in the area Of «sale of used railway car spare parts» you can use fast cleaning of spare parts (electric motors, diesel engines, suspension equipment, contact «horns», etc.) directly in the shop, without chemicals and water, with the effect of degreasing;

Equipment that can be cleaned by dry ice:

- Suspension cleaning

- Wheel cleaning

- Removing gum from the floor in the car

- Removing graffiti from the car

- Chewing gum removing

-

Railway car bodies

Dry ice cleaning advantages

- Reduced downtime for equipment and production

- Increased productivity (reduced cleaning time)

- Effective removal of bacteria (mold, Listeria, Salmonella).

- Degreasing of the surface

- No abrasive that can harm workers and equipment

- Improving the level of occupational safety in the workplace (reducing additional payments for harm and increasing the length of the working week)

- Improving the safety of storage and transportation of cleaning products (reducing surcharges for harm and increasing the length of the working week)

- Reducing the burden on the environment

- Reduction of production losses due to an accident

- Receive discounts on insurance rates in the social insurance Fund against industrial accidents and occupational diseases

- Reducing economic losses due to staff turnover

Cleaning Effect

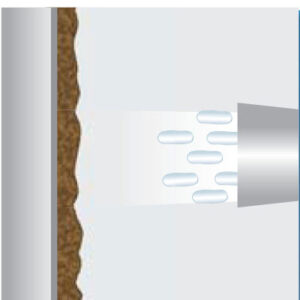

Mechanical impact of pellets

Pellets, accelerated in the air stream, gaining speed up to 300m/s and hit the dirt removing it

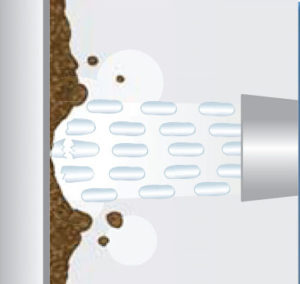

Thermal shock

When in contact with the contamination, the granule transmits a temperature of -79°C, which makes the contamination brittle, easier to break down and peel off

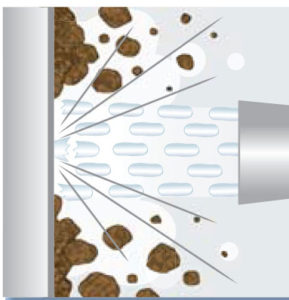

Sharp expansion

Dry ice particles are heated when they hit the pollution, as the kinetic energy of the movement turns into heat, after which the particles instantly turn into CO2 gas, expanding in volume by 700 times. This expansion is similar to a gas wedge that exfoliates the contamination.

Properties of dry ice

DRY ICE DOESN'T MELT

Dry ice is solid carbon dioxide (CO2), which, when heated, passes immediately into the gaseous phase, bypassing

the liquid phase. This process is called sublimation.

LOW TEMPERATURE

Dry ice has an extremely low temperature of -78.5°C. Only the temperature of liquid nitrogen, which is -195.8°C, is lower.

ECOLOGICAL SAFETY

Liquid carbon dioxide used for making dry ice is a by-product of various industries, so no additional greenhouse gases are generated during its production.

Comparison with traditional cleaning methods

Chemical cleaning

Significant time is required for complete or partial disassembly and installation, transportation to the site cleaning, requires the involvement of loading equipment and additional personnel, which leads to increasing the time and complexity of cleaning activities

Chemicals and solvents are dangerous to humans

Chemistry can damage the seals, isolation and others materials

Chemical residues can cause corrosion of metal components of equipment

Use of solvents is flammable and explosive

It is necessary to dispose of chemical waste after cleaning (up to 1 l / sq.metre)

Water jet cleaning

Significant time is required for complete or partial disassembly and installation, transportation to the site cleaning, requires the involvement of loading equipment and additional personnel, which leads to increasing the time and complexity of cleaning activities

It takes time to purge and dry the equipment from the remaining water

Risk of electric shock when working near electrical equipment

The water jet can damage the seals and soft materials of the equipment

Water residues can cause corrosion of metal components of the equipment

It is necessary to clean and dispose of dirty water after cleaning (60-200 l / sq.metre)

Abrasive blasting

Significant time is required for complete or partial disassembly and installation, transportation to the site cleaning, requires the involvement of loading equipment and additional personnel, which leads to increasing the time and complexity of cleaning activities

It takes time to purge and dry the equipment from the remaining abrasive particles

Danger of abrasive settling in in the lungs

Abrasive damages the surface of the equipment

Risk of abrasive particles getting into hard-to-reach areas of the equipment, which may cause it to malfunction

It is necessary to clean and dispose of the abrasive after cleaning (30-100 kg / sq.metre)

Dry ice blasting

Dry ice disappears immediately after cleaning

Dry ice is not a fire hazard

Dry ice is not explosive

Dry ice does not conduct electricity

Quick preparation before cleaning

It is possible to clean without stopping the process line

Minimum post-cleaning time after processing

Degreases and disinfects the surface

Contaminant types VS Air pressure

Light contaminants

- Engine oil deposits

- Fat deposits

- Fresh rust

- Liquid engine oil

- Mold and biodegradation

- Assembly foam

- Porous thermal insulation

- Dust and fluff

- Household dirt

Average contaminants

- Persistent engine oils

- Fresh rust

- Liquid mineral oils

- Lubricating grease

- Fresh glue

- Porous thermal insulation

- Paint on the wood

- Wood cleaning

- Soot

Hard contaminants

- Bitumen

- Dried glue

- Old rust

- Paint 400 µm

- Carbon

Supersonic nozzles are required