Месяц: Январь 2020

Oil & Gas

Petrochemical industry

Petrochemical industry

Target equipment

Tanks

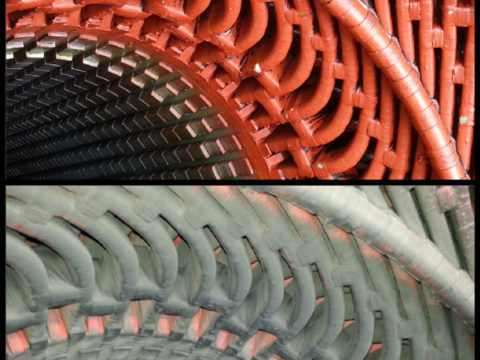

Electric generators and electric motors

Coils

Oil processing

Description of usage

The use of dry ice cleaning can improve the environmental friendliness and efficiency of repair and maintenance service of industrial equipment in the petrochemical industry. Dry ice cleaning is similar to sandblasting, but uses carbon dioxide in the form of solid particles as a consumable cleaning material. Soft and non-abrasive dry ice particles do not

damage the surface, so it can be used for cleaning precision components and equipment, such as electronics, mechanical transmissions, hard-to-reach components, seals, where cleaning with water, abrasives or chemicals is not allowed.

Using cryogenic blasting, you can perform:

cleaning of all power equipment (stator and rotor of turbogenerators, blades and diaphragms of the low-pressure steam turbine unit, live electrical panel components, transformer housing and insulators, gas and air cooler grids, surfaces of collapsible plate heat exchangers) directly in the shop, without chemicals and water, with the effect of degreasing, without damage;

cleaning of production equipment (conveyors, molds, molds, robots, furnaces, walls, floor and ceiling of the room) that is constantly polluted with dust and product residues;

Equipment that can be cleaned by dry ice:

- Reactor screens

- Tube bundles of the lateral shells

- Cleaning of internal and external walls of industrial premises

- Packaging service station

- Oil pumps

- Engines of oil pumping units

- Air coolers

- The removal of sulfur

- Preparation of surface vessels

- Stackers

- Rotary equipment

- Heat transfer equipment

- Gas pumping unit compressors

- Turbines of gas pumping units

Cryoblasting advantages

- Reduced downtime for equipment and production

- Increased productivity (reduced cleaning time)

- Effective removal of bacteria (mold, Listeria, Salmonella).

- Degreasing of the surface

- No abrasive that can harm workers and equipment

- Improving the level of occupational safety in the workplace (reducing additional payments for harm and increasing the length of the working week)

- Improving the safety of storage and transportation of cleaning products (reducing surcharges for harm and increasing the length of the working week)

- Reducing the burden on the environment

- Reduction of production losses due to an accident

- Receive discounts on insurance rates in the social insurance Fund against industrial accidents and occupational diseases

- Reducing economic losses due to staff turnover

Cleaning Effect

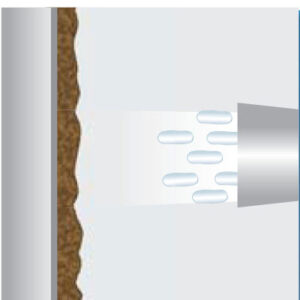

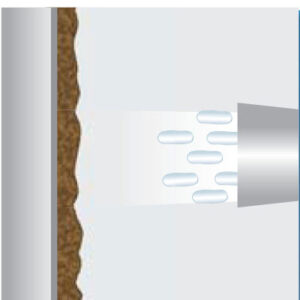

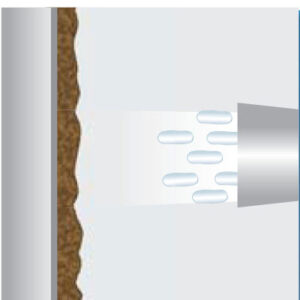

Mechanical impact of pellets

Pellets, accelerated in the air stream, gaining speed up to 300m/s and hit the dirt removing it

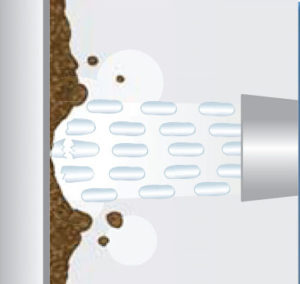

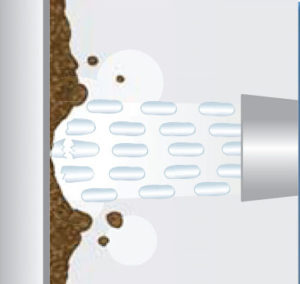

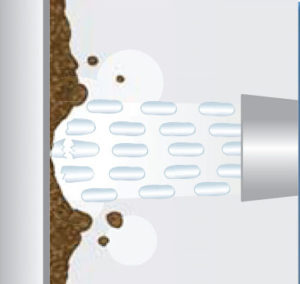

Thermal shock

When in contact with the contamination, the granule transmits a temperature of -79°C, which makes the contamination brittle, easier to break down and peel off

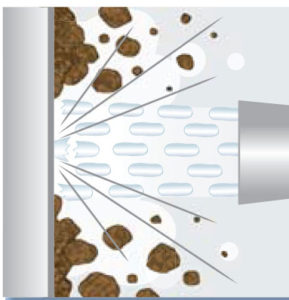

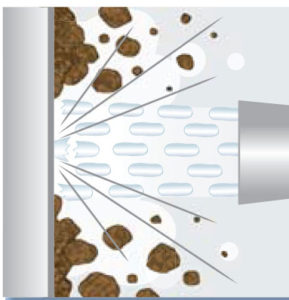

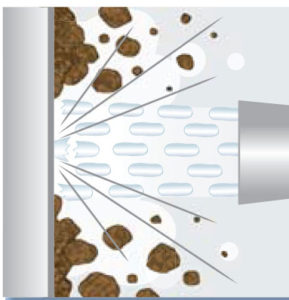

Sharp expansion

Dry ice particles are heated when they hit the pollution, as the kinetic energy of the movement turns into heat, after which the particles instantly turn into CO2 gas, expanding in volume by 700 times. This expansion is similar to a gas wedge that exfoliates the contamination.

Properties of dry ice

DRY ICE DOESN'T MELT

Dry ice is solid carbon dioxide (CO2), which, when heated, passes immediately into the gaseous phase, bypassing

the liquid phase. This process is called sublimation.

LOW TEMPERATURE

Dry ice has an extremely low temperature of -78.5°C. Only the temperature of liquid nitrogen, which is -195.8°C, is lower.

ECOLOGICAL SAFETY

Liquid carbon dioxide used for making dry ice is a by-product of various industries, so no additional greenhouse gases are generated during its production.

Comparison with traditional cleaning methods

Chemical cleaning

Significant time is required for complete or partial disassembly and installation, transportation to the site cleaning, requires the involvement of loading equipment and additional personnel, which leads to increasing the time and complexity of cleaning activities

Chemicals and solvents are dangerous to humans

Chemistry can damage the seals, isolation and others materials

Chemical residues can cause corrosion of metal components of equipment

Use of solvents is flammable and explosive

It is necessary to dispose of chemical waste after cleaning (up to 1 l / sq.metre)

Water jet cleaning

Significant time is required for complete or partial disassembly and installation, transportation to the site cleaning, requires the involvement of loading equipment and additional personnel, which leads to increasing the time and complexity of cleaning activities

It takes time to purge and dry the equipment from the remaining water

Risk of electric shock when working near electrical equipment

The water jet can damage the seals and soft materials of the equipment

Water residues can cause corrosion of metal components of the equipment

It is necessary to clean and dispose of dirty water after cleaning (60-200 l / sq.metre)

Abrasive blasting

Significant time is required for complete or partial disassembly and installation, transportation to the site cleaning, requires the involvement of loading equipment and additional personnel, which leads to increasing the time and complexity of cleaning activities

It takes time to purge and dry the equipment from the remaining abrasive particles

Danger of abrasive settling in in the lungs

Abrasive damages the surface of the equipment

Risk of abrasive particles getting into hard-to-reach areas of the equipment, which may cause it to malfunction

It is necessary to clean and dispose of the abrasive after cleaning (30-100 kg / sq.metre)

Dry ice blasting

Dry ice disappears immediately after cleaning

Dry ice is not a fire hazard

Dry ice is not explosive

Dry ice does not conduct electricity

Quick preparation before cleaning

It is possible to clean without stopping the process line

Minimum post-cleaning time after processing

Degreases and disinfects the surface

Виды загрязнений VS давление воздуха

Light contaminants

- Engine oil deposits

- Fat deposits

- Fresh rust

- Liquid engine oil

- Mold and biodegradation

- Assembly foam

- Porous thermal insulation

- Dust and fluff

- Household dirt

Average contaminants

- Persistent engine oils

- Fresh rust

- Liquid mineral oils

- Lubricating grease

- Fresh glue

- Porous thermal insulation

- Paint on the wood

- Wood cleaning

- Soot

Hard contaminants

- Bitumen

- Dried glue

- Old rust

- Paint 400 µm

- Carbon

Supersonic nozzles are required

Нефтегазохимическая отрасль

Нефтегазохимическая отрасль

Нефтегазохимическая отрасль

Целевое Оборудование

Резервуары

Электрогенераторы и электродвигатели

Теплообменники

Нефтепереработка

Описание применения

Применение очистки сухим льдом может повысить экологичность и эффективность ремонта и ТО промышленного оборудования в нефтегахохимической отрасли. Очистка сухим льдом схожа с пескоструйной очисткой, но с использованием диоксида углерода в форме твердых частиц в качестве расходного чистящего материала. Мягкие и неабразивные частицы сухого льда не

повреждают поверхность, поэтому её можно использовать для очистки прецизионных компонентов и оборудования, такого как: электроника, механические передачи, труднодоступные узлы, уплотнения, где очистка водой, абразивами или химией недопустима.

- очистку всего энергетического оборудования (статор и ротор турбогенераторов, лопатки и диафрагмы блока низкого давления паровой турбины, компоненты электрощита под напряжением, корпус и изоляторы трансформаторов, решетки газо- и воздухоохладителей, поверхности разборных пластинчатых теплообменников) прямо в цеху, без химии и воды, с эффектом обезжиривания, без повреждения;

- очистку производственного оборудования (конвейеры, пресс-формы, литформы, роботы, печи, стены, пол и потолок помещения), которые постоянно загрязняется пылью и остатками продукции;

Оборудование, которое можно чистить сухим льдом:

- Экраны реакторов

- Трубные пучки боковых оболочек

- Чистка внутренних и наружных стен промышленных помещений

- Упаковочные столы

- Нефтяные насосы

- Двигатели НПА

- Воздухоохладители

- Удаление серы

- Подготовка поверхности сосудов

- Укладчики

- Ротационное оборудование

- Теплообменное оборудование

- Ротационное оборудование

- Компрессоры ГПА

- Трубины ГПА

Machine building

Machine building

Machine building

Target Equipment

Injection molding tools

Welding and painting lines

Stamp machines

Corrosion on metals

Description of usage

The accumulation of dirt, soot, fat and oil deposits on production lines and equipment can cause the equipment to malfunction and cause the line to stop. Manual, hydrodynamic, abrasive and chemical cleaning are used as rarely as possible to reduce the number of planned downtime of production lines, which lead to loss of revenue for the enterprise. Dry ice jet cleaning provides a fast, safe, non-toxic and cost-effective solution for cleaning industrial equipment, machinery, machine tools and assembly equipment conveyor belts, welding and painting robots, and even manufactured products.

Equipment that can be cleaned by dry ice:

- Welding robot

- Paint robots

- Injection molds

- Molds

- Electromotors

- Heat transfer equipment

- Cleaning walls and floors

- Removing carbon deposits

- Removing oils

- Removal of soot

- Removal of dirt

Cryoblasting advantages

- Reduced downtime for equipment and production

- Increased productivity (reduced cleaning time)

- Effective removal of bacteria (mold, Listeria, Salmonella).

- Degreasing of the surface

- No abrasive that can harm workers and equipment

- Improving the level of occupational safety in the workplace (reducing additional payments for harm and increasing the length of the working week)

- Improving the safety of storage and transportation of cleaning products (reducing surcharges for harm and increasing the length of the working week)

- Reducing the burden on the environment

- Reduction of production losses due to an accident

- Receive discounts on insurance rates in the social insurance Fund against industrial accidents and occupational diseases

- Reducing economic losses due to staff turnover

Cleaning Effect

Mechanical impact of pellets

Pellets, accelerated in the air stream, gaining speed up to 300m/s and hit the dirt removing it

Thermal shock

When in contact with the contamination, the granule transmits a temperature of -79°C, which makes the contamination brittle, easier to break down and peel off

Sharp expansion

Dry ice particles are heated when they hit the pollution, as the kinetic energy of the movement turns into heat, after which the particles instantly turn into CO2 gas, expanding in volume by 700 times. This expansion is similar to a gas wedge that exfoliates the contamination.

Properties of dry ice

DRY ICE DOESN'T MELT

Dry ice is solid carbon dioxide (CO2), which, when heated, passes immediately into the gaseous phase, bypassing

the liquid phase. This process is called sublimation.

LOW TEMPERATURE

Dry ice has an extremely low temperature of -78.5°C. Only the temperature of liquid nitrogen, which is -195.8°C, is lower.

ECOLOGICAL SAFETY

Liquid carbon dioxide used for making dry ice is a by-product of various industries, so no additional greenhouse gases are generated during its production.

Comparison with traditional cleaning methods

Chemical cleaning

Significant time is required for complete or partial disassembly and installation, transportation to the site cleaning, requires the involvement of loading equipment and additional personnel, which leads to increasing the time and complexity of cleaning activities

Chemicals and solvents are dangerous to humans

Chemistry can damage the seals, isolation and others materials

Chemical residues can cause corrosion of metal components of equipment

Use of solvents is flammable and explosive

It is necessary to dispose of chemical waste after cleaning (up to 1 l / sq.metre)

Water jet cleaning

Significant time is required for complete or partial disassembly and installation, transportation to the site cleaning, requires the involvement of loading equipment and additional personnel, which leads to increasing the time and complexity of cleaning activities

It takes time to purge and dry the equipment from the remaining water

Risk of electric shock when working near electrical equipment

The water jet can damage the seals and soft materials of the equipment

Water residues can cause corrosion of metal components of the equipment

It is necessary to clean and dispose of dirty water after cleaning (60-200 l / sq.metre)

Abrasive blasting

Significant time is required for complete or partial disassembly and installation, transportation to the site cleaning, requires the involvement of loading equipment and additional personnel, which leads to increasing the time and complexity of cleaning activities

It takes time to purge and dry the equipment from the remaining abrasive particles

Danger of abrasive settling in in the lungs

Abrasive damages the surface of the equipment

Risk of abrasive particles getting into hard-to-reach areas of the equipment, which may cause it to malfunction

It is necessary to clean and dispose of the abrasive after cleaning (30-100 kg / sq.metre)

Dry ice blasting

Dry ice disappears immediately after cleaning

Dry ice is not a fire hazard

Dry ice is not explosive

Dry ice does not conduct electricity

Quick preparation before cleaning

It is possible to clean without stopping the process line

Minimum post-cleaning time after processing

Degreases and disinfects the surface

Contaminant types VS Air pressure

Light contaminants

- Engine oil deposits

- Fat deposits

- Fresh rust

- Liquid engine oil

- Mold and biodegradation

- Assembly foam

- Porous thermal insulation

- Dust and fluff

- Household dirt

Average contaminants

- Persistent engine oils

- Fresh rust

- Liquid mineral oils

- Lubricating grease

- Fresh glue

- Porous thermal insulation

- Paint on the wood

- Wood cleaning

- Soot

Hard contaminants

- Bitumen

- Dried glue

- Old rust

- Paint 400 µm

- Carbon

Supersonic nozzles are required

Машиностроение

Машиностроение

Машиностроение

Целевое Оборудование

Литьевые оснастки

Линии сварки и покраски

Штамп-автоматы

Коррозия на металлах

Описание применения

Накопление грязи, сажи, жировых и масляных отложений на производственных линиях и оборудовании может привести к неправильному функционированию оборудования и остановке линии. Ручная, гидродинамическая, абразивная и химическая очистки применяются максимально редко для уменьшения количества плановых простоев производственных линий, которые ведут к потере дохода предприятия. Струйная очистка сухим льдом обеспечивает быстрое, безопасное, нетоксичное и экономичное решение для очистки промышленного оборудования, машин, станков и сборочного

конвейера, сварочных и покрасочных роботов, и даже производимой продукции.

Оборудование, которое можно чистить сухим льдом:

- Сварочные роботы

- Покрасочные роботы

- Литьевые формы

- Пресс-формы

- Электродвигатели

- Теплообменное оборудование

- Очистка стен и пола

- Удаление нагара

- Удаление масел

- Удаление сажи

- Удаление грязи

Energy

Energy field

Energy

Target application

Hydrogenerators

Turbogenerators

Transformers

Heat transfer equipment

Description of usage

Professionals in the field of power generation know, that the maximum performance can be achieved by clean equipment. However, the requirement for minimal downtime leads to an increase in the period between repairs and maintenance service. Dry ice cleaning provides a reliable, fire, electrical and environmental saving cleaning process, that can be used even without cooling, without complete or partial dismantling of the equipment, being cleaned directly in the shop. Contamination of the running parts of gas and steam turbines, windings of electric generators, insulators of transformers leads to a drop in efficiency and a decrease in electricity generation. In addition, the downtime normally required for cleaning can be reduced by up to 65%.

Cryoblasting advantages

- Reduced downtime for equipment and production

- Increased productivity (reduced cleaning time)

- Effective removal of bacteria (mold, Listeria, Salmonella).

- Degreasing of the surface

- No abrasive that can harm workers and equipment

- Improving the level of occupational safety in the workplace (reducing additional payments for harm and increasing the length of the working week)

- Improving the safety of storage and transportation of cleaning products (reducing surcharges for harm and increasing the length of the working week)

- Reducing the burden on the environment

- Reduction of production losses due to an accident

- Receive discounts on insurance rates in the social insurance Fund against industrial accidents and occupational diseases

- Reducing economic losses due to staff turnover

Cleaning Effect

Mechanical impact of pellets

Pellets, accelerated in the air stream, gaining speed up to 300m/s and hit the dirt removing it

Thermal shock

When in contact with the contamination, the granule transmits a temperature of -79°C, which makes the contamination brittle, easier to break down and peel off

Sharp expansion

Dry ice particles are heated when they hit the pollution, as the kinetic energy of the movement turns into heat, after which the particles instantly turn into CO2 gas, expanding in volume by 700 times. This expansion is similar to a gas wedge that exfoliates the contamination.

Properties of dry ice

DRY ICE DOESN'T MELT

Dry ice is solid carbon dioxide (CO2), which, when heated, passes immediately into the gaseous phase, bypassing

the liquid phase. This process is called sublimation.

LOW TEMPERATURE

Dry ice has an extremely low temperature of -78.5°C. Only the temperature of liquid nitrogen, which is -195.8°C, is lower.

ECOLOGICAL SAFETY

Liquid carbon dioxide used for making dry ice is a by-product of various industries, so no additional greenhouse gases are generated during its production.

Comparison with traditional cleaning methods

Chemical cleaning

Significant time is required for complete or partial disassembly and installation, transportation to the site cleaning, requires the involvement of loading equipment and additional personnel, which leads to increasing the time and complexity of cleaning activities

Chemicals and solvents are dangerous to humans

Chemistry can damage the seals, isolation and others materials

Chemical residues can cause corrosion of metal components of equipment

Use of solvents is flammable and explosive

It is necessary to dispose of chemical waste after cleaning (up to 1 l / sq.metre)

Water jet cleaning

Significant time is required for complete or partial disassembly and installation, transportation to the site cleaning, requires the involvement of loading equipment and additional personnel, which leads to increasing the time and complexity of cleaning activities

It takes time to purge and dry the equipment from the remaining water

Risk of electric shock when working near electrical equipment

The water jet can damage the seals and soft materials of the equipment

Water residues can cause corrosion of metal components of the equipment

It is necessary to clean and dispose of dirty water after cleaning (60-200 l / sq.metre)

Abrasive blasting

Significant time is required for complete or partial disassembly and installation, transportation to the site cleaning, requires the involvement of loading equipment and additional personnel, which leads to increasing the time and complexity of cleaning activities

It takes time to purge and dry the equipment from the remaining abrasive particles

Danger of abrasive settling in in the lungs

Abrasive damages the surface of the equipment

Risk of abrasive particles getting into hard-to-reach areas of the equipment, which may cause it to malfunction

It is necessary to clean and dispose of the abrasive after cleaning (30-100 kg / sq.metre)

Dry ice blasting

Dry ice disappears immediately after cleaning

Dry ice is not a fire hazard

Dry ice is not explosive

Dry ice does not conduct electricity

Quick preparation before cleaning

It is possible to clean without stopping the process line

Minimum post-cleaning time after processing

Degreases and disinfects the surface

Contaminant types VS Air pressure

Light contaminants

- Engine oil deposits

- Fat deposits

- Fresh rust

- Liquid engine oil

- Mold and biodegradation

- Assembly foam

- Porous thermal insulation

- Dust and fluff

- Household dirt

Average contaminants

- Persistent engine oils

- Fresh rust

- Liquid mineral oils

- Lubricating grease

- Fresh glue

- Porous thermal insulation

- Paint on the wood

- Wood cleaning

- Soot

Complicated contaminants

- Bitumen

- Dried glue

- Old rust

- Paint 400 µm

- Carbon

Supersonic nozzles are required