Transformer - globally new dry ice blaster Use up 20 mm pellets for power and economical cleaning

Model "One" only for small pellets (1.6 and 3 mm)

Cleaning with only 3 mm pellets

Without the possibility of changing the size of the granules (degree of aggressiveness/softness of cleaning)

Air consumption from 3500 l / min

With lower compressor performance, the cleaning efficiency decreases

Super sonic nozzles

Reduction of dry ice consumption due to maximum air acceleration in nozzles with a special profile

Model "TRANSFORMER" with internal grinder (3-20 mm pellets)

Use any pellets

Increasing the storage time and extending the cleaning period

Cutting of pellets into particles with determined size

Reduction of dry ice consumption due to faster acceleration of small particles. Choosing of size od pearticles 1, 1.5, 2, 2.5, 3 mm

Air consumption 800 L/min and more

With small particles, you can use nozzles with a smaller wire cross-section, which save compressed air.

Super sonic nozzles

Reduction of dry ice consumption due to maximum air acceleration in nozzles with a special profile

The revolutionary grinder in Transformer

Why to grind large pellets?

Historically, 1-1.6 mm pellets have been used for dry ice cleaning, but since they evaporated too quickly, users switched to 3 mm granules, sacrificing cleaning efficiency. Advantages of fine particles of solid dry ice:

- The finer the particles, the more they are accelerated in the nozzle and better clean;

- The finer the particles, the denser the cleaning jet (particles are better distributed over the cleaning spot).

For example, 16 mm pellets have up to 5 times less specific surface area to weight, due to which they evaporate more slowly, which in turn gives the following advantages:

- The loss of pellets during transportation is reduced;

- The loss of pellets during storage is reduced;

- The loss of pellets during the usage is reduced.

Also, the gentle technology of cutting granules from IRBISTECH provides the following advantages:

- Any dry ice pellets can be used;

- The pellets are almost equal in size;

- You can independently choose the target size of the particles range: 0.3-0.7, 1-2 and 2-3 mm.

Comparison of granule grinding technologies

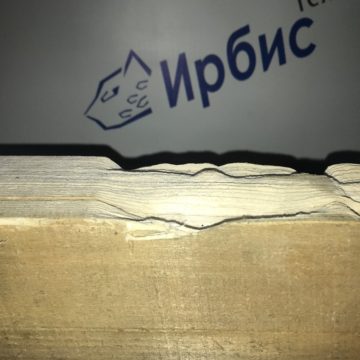

Shearing

You can use:

- 3 mm rize pellets

- 6-16 mm pellets

Shearing-the body is divided into parts of predetermined sizes and shapes. The process is fully controlled.*

This grinding technology is used in the dry ice cleaning machine model «TRANSFORMER«.

Shaving

You can use:

- 3 mm rize pellets

- 6-16 mm pellets

- Slice and bricks

Shaving -the blades scrape a thin layer from the body of the pellet, resulting in the formation of small particles resembling flakes and dust.

Compressing

You can use:

- 3 mm rize pellets

Compressing – the body under the action of load is deformed throughout the volume and, when the internal stress exceeds the compressive strength, is destroyed. As a result of this destruction, particles of various sizes and shapes are obtained.

* Technological publication » Grinding in the chemical industry”, Sidenko P. M., Publisher: Chemistry, Year: 1977

Supersonic nozzles for the ONE and Transformer

Dry ice super sonic nozzle

What distinguishes the IRBISTECH nozzles?)

We have been continuously optimizing our nozzles since 2016.

It is known that the specific consumption of pellets for cleaning 1 square meter of dirt depends on:

- Source compressed air pressure

- Compressed air consumption of the source

- Dry ice cleaning machine throughput

But not a lot of customers pay attention to such parameters as:

- Nozzle length (affects how long the pellet can accelerate)

- Nozzle length (affects how long the pellet can accelerate) Speed distribution in the nozzle (affects how fast the pellet can accelerate)

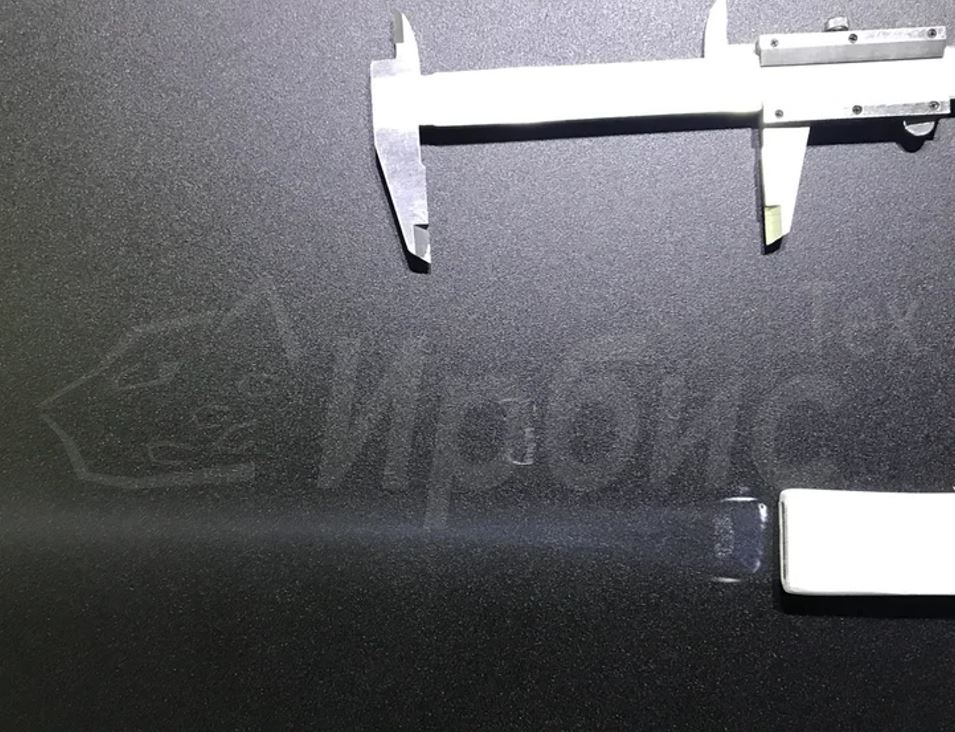

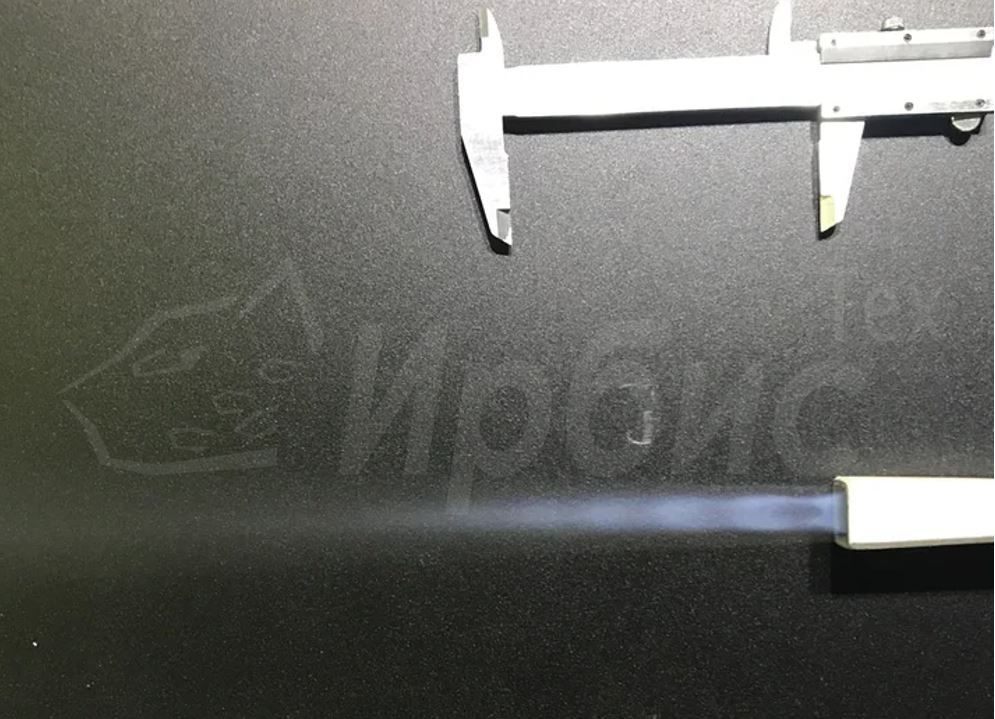

Long supersonic nozzles from IRBIT are able to keep the supersonic flow along the entire length of the long nozzle, due to which the pellets acquire a higher speed. In flat nozzles, when their length increases, the supersonic flow is disrupted due to boundary layers.

Schematic diagram of the Transformer

Features

Designed in accordance with the:

- IEC 60204-1 Safety of machinery;

- IEC 60364-4-41:2005 Protection against electric shock.

Designed in accordance with the:

- ISO 12100:2010 «Safety of machinery — General principles for design — Risk assessment and risk reduction.

Electrical cables are used according to the VDE standard

Easy-to-use operator panel

PLC-free automation

Flexible pneumatic wheels

Kit for both blasters

Lightweight and flexible jet hose (4.5 mm)

Functional operator handle (24VDC)

Case

Mini nozzles (500-2000 L/min)

Flat universal nozzle (3500 OR 5000 l/min)

Individual long supersonic nozzle (3500 OR 5000 l/min)

Protective headphones

Protective glasses

Frost-resistant gloves

Scoop for ice

Spare parts and accessories

Angular nozzles

Super-wide nozzles

Extension of the electro-cryogenic hose

Operator's gun

Aluminum operator's gun

Spare set of seals and portion shaft

Technical Specifications

- Consumed pellets size (TRANSFORMER): 3, 6, 9, 16 mm

- Consumed pellets size (ONE): 3 mm

- Pellet consumption: up to 120 kg/hour

- Cleaning pressure: up to 12 atm

- Air consumption: up to 10 000 liters/min

- 0.55 kW (ONE) и 1.3 (Transformer) at 220VAC (2P+E);

- 115 kg (ONE) и 130 kg (Transformer);

- 963x461x1262 mm

Testimonials

Performed demonstrations

Subsidiary of Rostec

PJSC Tatneft

JSC RusHydro

PJSC GAZ

PJSC Tatenergo

Nestle

Selecting a compressor for cleaning

Removal of dirt of light complexity, which can be almost removed with a rag by hand (for example: oil deposits, light deposits, loose and brittle dirt, industrial dust, street dirt): working pressure 6-7 atm and 3 cubic meters / min according to FAQ

For the removal of medium-sized dirt (including paint, deposits, grease deposits, food soot, dried glue and bitumen): working pressure 8-9 atm and 5-6 cubic meters / min according to FAQ

For the removal of high-complexity contaminants (including old rust,» stone » deposits on the steam turbine, polymer and fire-fighting paint): working pressure of 10-12 ATM and 7-9 cubic meters / min according to FAQ

FAQ (Frequently Asked Questions)

1. What distinguishes pellets from ordinary dry ice, which is used in ice cream makers on the street?

Dry ice granules are obtained by pressing at a pressure of 160-200 atm, due to which its density becomes very high, and the lumen of the granules is almost transparent. Regular blocks of dry ice, white in color and very fragile. granules, in turn, are loose and solid, so they are used for high-quality cleaning.

2. Can the briquettes/blocks be used for cleaning in machine ONE?

No, only small cylindrical pellets with a diameter of 1.6 or 3 mm.

3. Can the briquettes/blocks be used for cleaning in a machine with a grinder?

The grinder in the TRANSFORMER machine can only accept loose pellets with a size of 3 to 20 mm in diameter, it does not work with blocks.

4. Where does dry ice go after cleaning?

It immediately evaporates and turns into CO2 gas.

5. Where does the contamination go after cleaning?

It flies off in the direction where the air jet with pellets blows. dry ice is inert and does not interact with dirt and the surface to be cleaned.

6. Will the dry ice cleaning process affect the breath, because CO2 is released?

When cleaning, a screw compressor is used, which supplies a large amount of air during the cleaning process through the nozzle, so in 99.99% of cases, there are no breathing problems. if the room is closed, has a small volume or low ceilings, and the container with pellets is located in it, then there is a need to ensure constant ventilation of the room. This is explained by the fact that CO2 is heavier than air.

7. Where can I get dry ice?

Dry ice is sold in some large cities of Russia by independent producers, so dry ice is a market commodity, not a monopoly. In order to find out the nearest manufacturer of dry ice, you can contact IRBISTECH, our specialists are always ready to provide this information.

See the article «Organisation of dry ice production«

8. How to store dry ice?

Storage is carried out in special industrial thermal containers on wheels with a capacity of 100,200,300 kg of ice; there are also inexpensive household containers for 50-75 kg with good characteristics, made of foam. All these containers have basic properties: tightness and a wall thickness of 10 cm. Some local dry ice producers provide containers for rent.

9. How quickly does dry ice evaporate in containers?

5-8% of the volume per day. The rate of evaporation depends on the time of year. Before the first opening of the container, 3-millimeter pellets can be safely stored for up to three days without changing their properties. Large pellets with a diameter of 6-20 mm evaporate more slowly than pellets with a diameter of 3 mm, due to the smaller specific area per 1 kg of pellets.

10. What can be break in the machine?

In the machine, everything is thought out so that, with proper operation, it will serve for many years. In case of violation of the operating rules, the following damages may occur:

- breakage of the operator’s handle when it is hit hard;

- damage and abrasion of the batch shaft with a seal, knives and shredder sieves in case of frequent ingress of solid dust into the hopper or through the air flow, as well as in case of a single ingress of a large solid object into the structure, such as, for example, a nut or bolt.

11. What are the requirements for compressed air?

For uninterrupted operation of the plant, the compressed air must have a low humidity (the maximum value is 5% relative humidity, the dew point is below 0°C). The compressed air must be free of oil, dirt and large particles. The compressed air must, at a minimum, comply with the air quality indicators according to «ISO 8573, class 3».

12. Which compressor should be used for cleaning?

Compressor for a point solution: removal of dirt of light complexity, which are easily removed by hand with a rag (for example: oil deposits, light deposits, crumbly and brittle dirt, industrial dust, street dirt): working pressure of 7 ATM and 3 cubic meters / min according to FAD (estimated price 330,000 rubles. with an electric drive of 18 kW);

Universal compressor for cleaning services: for removing medium-complexity dirt (including paint, deposits, grease deposits, food soot, dried glue and bitumen): working pressure 8-9 ATM and 4-5 cubic meters / min according to FAD (estimated price 600,000 rubles. with an electric drive for 30 kW);

Special applications: for removing high-complexity contaminants (including old rust,» stone » deposits on a steam turbine, polymer and fire-fighting paint): working pressure of 10-12 ATM and 7 cubic meters / min according to FAD (estimated price 900,000 rubles with an electric drive of 55 kW).

Light contaminations Cleaning examples

Persistent contaminations Cleaning examples

IrbisTech YouTube channel

On our video channel you can find a lot of videos with the cleaning various contaminations

Four year long Development

First sample

First generation

Second generation (Transformer)

Parameters optimisation

While testing the samples the In the process of testing the samples, researches were carried out to optimize the power of engines, the consumption of pellets, the materials of rubbing materials, and the operation of electronic components

Low temperature testings

Components and units of the machine were tested on the long lasting dry ice temperature impact, thus, the study of fault tolerance during long-term operation was carried out.

Resource tests

The rubbing parts were analyzed for the rate of wear, which made it possible to develop a long-lasting dry ice cleaning system